About the BULLET

Advantages of using the Bullet™ Positive Displacement System:

- Greater Production Capabilities: Continuous Sorting/Counting No need for a vacuum tight bin at each outlet so no need to stop and dump!

- Greatly Enhances Existing Vacuum Systems: The key bottleneck in a busy soil room is the belt conveyor. Adding a Bullet™ to a standard vacuum system will increase the production by delivering the few key specific goods directly into the slings or sling carts, relieving the belt.

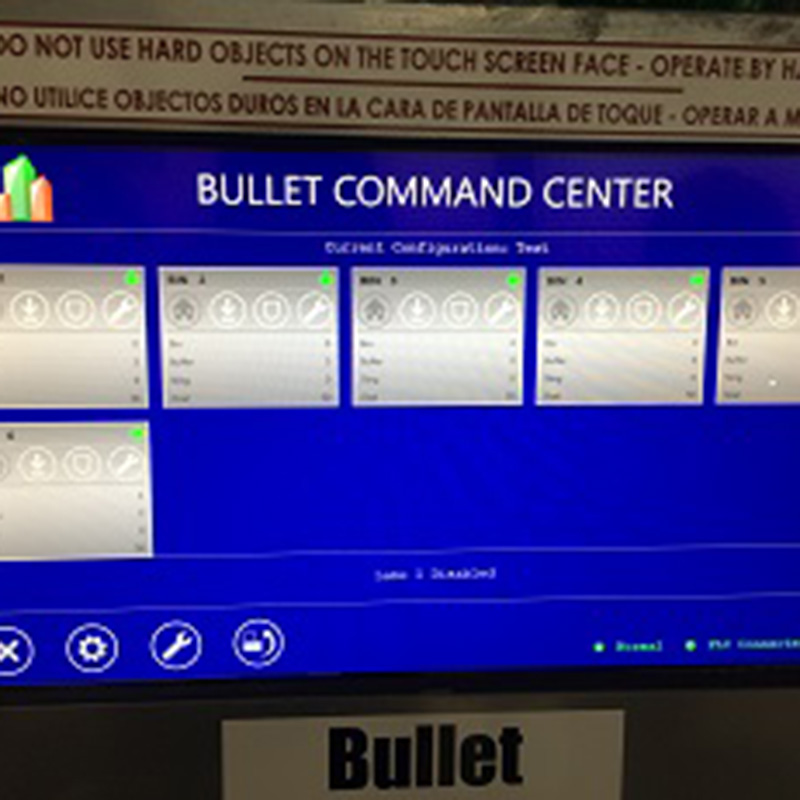

- RFID Enabled - Totally chip driven or a Touch Screen Command or Both Correct Counting and Weighing: Each operator has a single motor feeding the suction tube keeping the velocity the same throughout the delivery process - "Same Velocity = Accurate Counting".

- Greater Versatility to Fit & Adapt A Bullet™ System is totally modular in design The Bullet™ is the only system to use RFID and specifically reject non-read/non-register into a single location while placing all other items into their appropriate location in one movement.

- Greater Versatility to Fit & Adapt Why did Automation Dynamics develop the Bullet™? It is the fastest and most versatile way to move textile products - bar none! Some plants' mix of goods and business require a multi-equipment approach to handling, moving, weighing, counting, and sorting goods. Bullet™ by design will do what vacuum systems cannot.

- Technical Specifications The Bullet™ design changes drastically depending on your plant's needs. The Bullet™ uses 5, 7, 10, or 15 horsepower motors and several feet of 7 inch pvc tube to take material from the receiving end to the delivery end.